Urethane Casting

Get custom plastic molded prototypes and production parts in as few as 10 business days. We provide expert engineering reviews and $500 off your first mold. Dozens of materials and finishes are available.

Upload 3D CAD File to Start A New Molding Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

What Is Urethane Casting?

Urethane Casting is a low-mid volumes process for customers looking for high quality, precise, and consistent parts, fast.

Stratasys Direct developed a proprietary approach to master pattern production that is guaranteed to deliver consistency and quality in your cast components.

Urethane Casting Expertise & Capacity

We operate the largest polymer casting enterprise in North America – both in terms of production capacity and part size capabilities.

Urethane casting gives companies a first-to-market advantage and first shots within 7-10 business days.

This allows companies to get their products on shelves long before hard-tooling for traditional injection molding could be completed.

Accuracy & Consistency with Urethane Casting

Get the first-to-market advantage through the use of quick-turn, 3D printed master patterns and fast curing silicone molds.

Urethane Casting Applications

PRODUCTION PARTS

Urethane casting molds can yield up to 75 repeatable production components.

FUNCTIONAL PROTOTYPES

Urethane casting molds can yield up to 75 repeatable production components.

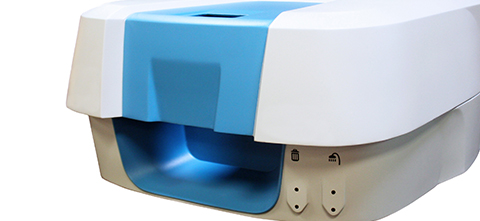

MEDICAL DEVICE HOUSINGS

Cast cosmetic housings for electronic medical devices with healthcare-friendly materials.

Urethane Casting Materials

Material | Description | Benefits | Applications | Properties |

|---|---|---|---|---|

| Our high Izod impact urethane for pre-production and production applications; Certified to USP Class VI requirements and RoHS 2 / REACH SVHC Compliant |

|

| DATASHEET | |

| Our most widely used urethane for production applications with a UL 94 V-0 flammability listing at .1” thickness. RoHS 2 / REACH SVHC Compliant |

|

| DATASHEET | |

| Used for fire retardant applications in thinner sections. Meets the requirements of FAR 28.853 Part 1, (a) (1) (i) for flammability in 0.043 inch (1.1 mm) thickness; RoHS 2 / REACH SVHC |

| Durable, high-impact strength urethane with FAR 25.853 flammability rating | DATASHEET | |

| Provides a unique combination of physical properties for very tough and durable parts and assemblies. Good rigidity and stiffness due to its very high modulus. High tensile and impact strength for excellent resistance to breakage. |

|

| DATASHEET | |

| Used for very high temp applications; Heat deflection of 346F at 264 psi test; RoHS 2 / REACH SVHC Compliant |

|

| DATASHEET | |

| Used for applications that require flexibility having a low Flexural Mod. of 116,061 psi and high Izod Impact strength of 4.40ft.lbs/inch. Simulates Polypropylene. | Very good impact resistance | Prototype parts having mechanical properties close to polypropylene, with features requiring superior elongation like living hinges | DATASHEET | |

| Used for applications that require a clear material; can also be tinted easily; has good heat resistance and best for smaller geometries. |

|

| DATASHEET | |

| Used primarily in production applications of medium to large parts that require MRI transparency and a UL 94V0 registered flame rating. |

|

| DATASHEET | |

| Used primarily in production applications of smaller parts that require MRI transparency and a UL 94V0 registered flame rating. |

|

| DATASHEET | |

| High impact rigid 78 Shore D material. |

|

| Contact an Engineer | |

| A glass composite sheet filled version of our most widely used urethane for production applications with a UL 94 V-0 flammability listing at .1” thickness. RoHS 2 / REACH SVHC Compliant. Parts exhibit enhanced flexural and impact properties. |

|

| DATASHEET | |

| A glass composite sheet filled version of our MRI transparent production urethane used for medium to large parts that require MRI transparency and a UL 94V0 registered flame rating. Parts exhibit enhanced flexural and impact properties. |

|

| DATASHEE |

Material | Description | Benefits | Applications | Properties |

|---|---|---|---|---|

| Extra Soft, 5 Shore A Elastomer used for production parts, special effects props and medical training models; RoHs/REACH Compliant |

|

| DATASHEET | |

| Soft, 15 Shore A Elastomer used for production parts, special effects props and medical training models; RoHs/REACH Compliant |

|

| DATASHEET | |

| Soft, 25 Shore A Elastomer used for production parts, special effects props and medical training models; RoHs/REACH Compliant |

|

| DATASHEET | |

| Soft, 30 Shore A Elastomer used for production parts, over molding, special effects props and medical training models; RoHs/REACH Compliant |

|

| DATASHEET | |

| Medium Soft, similar to a pencil eraser 40 Shore A Elastomer used for production parts, over molding, special effects props and medical training models; RoHs Compliant |

|

| DATASHEET | |

| Medium Soft, similar to a Door Seal 50 Shore A Elastomer used for production parts, over molding, special effects props and medical training models; RoHs Compliant |

|

| DATASHEET | |

| Medium Hard, 60 Shore A Elastomer used for production parts, over molding, special effects props and medical training models; RoHs Compliant |

|

| DATASHEET | |

| Medium Hard, similar to automotive tire tread 70 Shore A Elastomer used for production parts and special effects props; RoHs Compliant |

|

| DATASHEET | |

| Hard, similar to Hydraulic O-Rings 80 Shore A Elastomer used for production parts and special effects props; RoHs Compliant |

|

| DATASHEET | |

| Hard, similar to a squeegee 90 Shore A Elastomer used for production parts and special effects props; RoHs Compliant |

|

| DATASHEET | |

| Hard, similar to a shopping cart wheel 95 Shore A Elastomer used for production parts, strain reliefs and special effects props; RoHs Compliant |

|

| DATASHEET |

Material | Description | Benefits | Applications | Properties |

|---|---|---|---|---|

| Soft, 15 Shore A silicone rubber used for preproduction and production parts like keypads, seals and gaskets. | Platinum based silicone |

| DATASHEET | |

| Soft, 30 Shore A silicone rubber used for preproduction and production parts like keypads, seals and gaskets. | Platinum based silicone |

| DATASHEET | |

| Medium Soft, 40 Shore A silicone rubber used for preproduction and production parts like keypads, seals and gaskets. | Platinum based silicone |

| DATASHEET | |

| Medium Soft, 50 Shore A silicone rubber used for preproduction and production parts like keypads, seals and gaskets. | Platinum based silicone |

| DATASHEET | |

| Medium hard, 60 Shore A silicone rubber used for preproduction and production parts like keypads, seals and gaskets. | Platinum based silicone |

| DATASHEET |

Our Urethane Casting Quality Assurance

Frequently Asked Questions About Injection Molding

How many parts can you get from a single Urethane Casting mold?

It depends on several factors, but a Urethane Casting mold typically yields 15 to 25 parts.

One factor that may reduce the lifespan of a mold is the geometry—sharp edges or deep undercuts tend to deteriorate more quickly.

VolumeCast—a process that utilizes hybrid tooling and proprietary casting techniques—can have an extended mold life, up to between 35 and 75 units.

What is the largest size of a part can you cast in urethane?

The maximum size for a cast urethane part is approximately 1,000 cubic inches, but large parts can be reviewed on an individual basis to determine compatibility with our casting processes.

How soon can I expect to receive a urethane part after I place an order?

Upon receiving CAD data, typical cast urethane projects can be shipped in 7 to 10 days.